Imparting skills that lend a competitive edge for a lasting career in automobiles

Program Scope

| 368 Hours |

| 4 Hours per day |

| Hybrid |

Program Overview

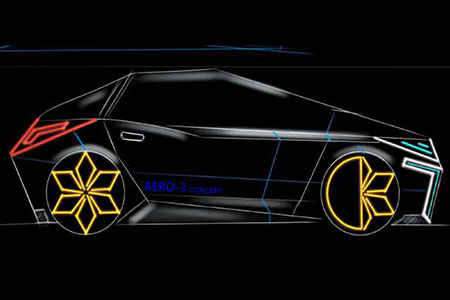

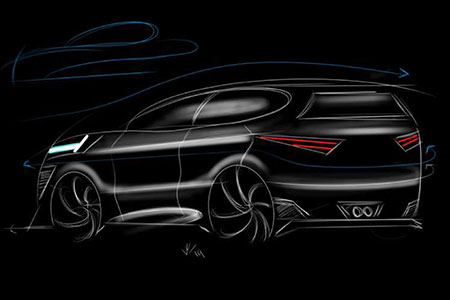

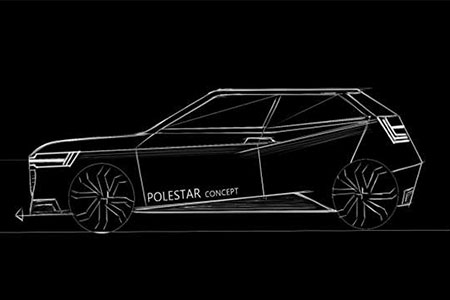

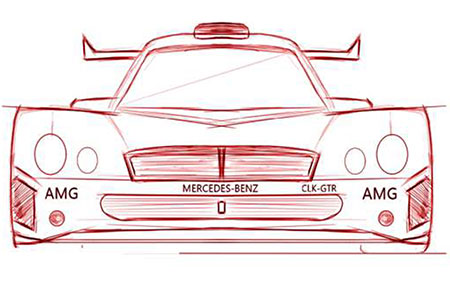

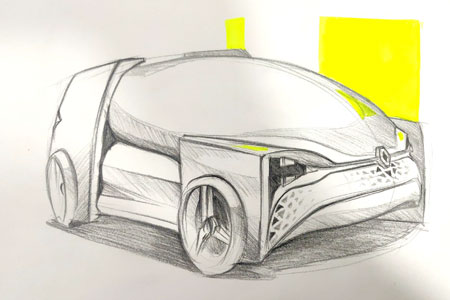

A comprehensive program, its scope covers the full spectrum - from automotive sketching to prototyping of components, assemblies, and systems that give a fillip to the appearance and ergonomics of automobiles. The highlights of the program include:

| Focus on Skills in Demand |

| Workplace Exposure through Industry Visits |

| Projects Based Training |

| Placements / Employment Orientation |

Take the right step towards a

career that give you a solid start

Key Subjects / Domains

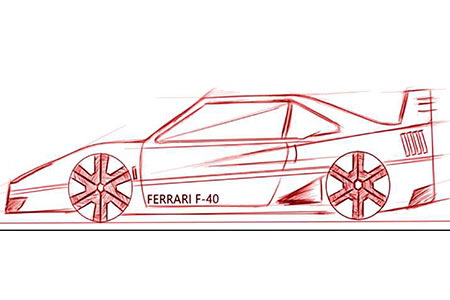

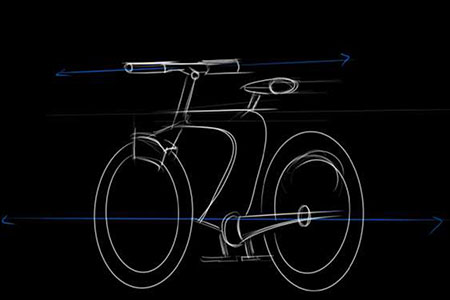

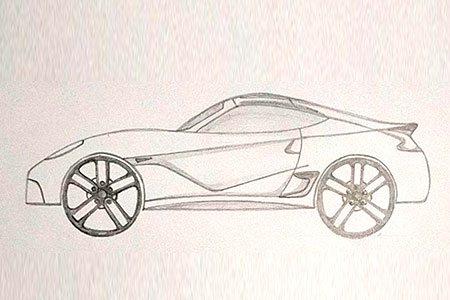

Gives a strong foundation in the fundamentals of industrial design and imparts sketching skills covering automotive body layouts to proportions.

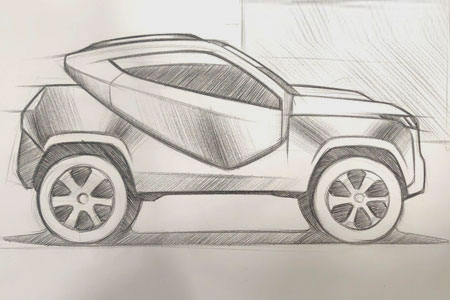

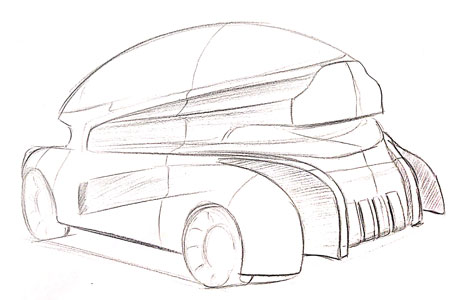

A vehicle before its manufacturing, undergoes several long procedures of modeling. These models are built using clay to get the final impression of the car. The course of clay modeling covers the following topics:

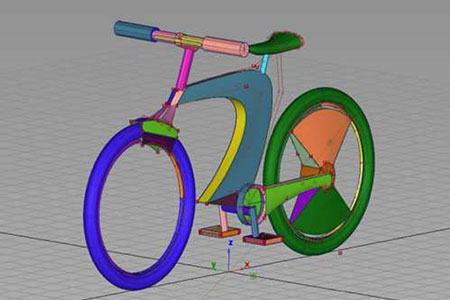

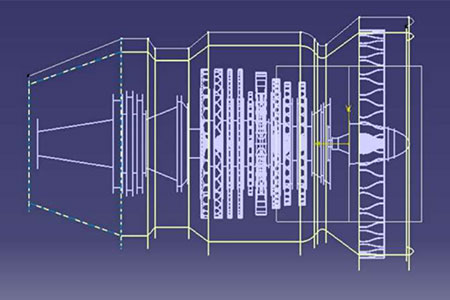

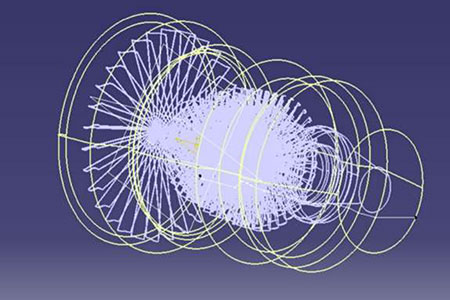

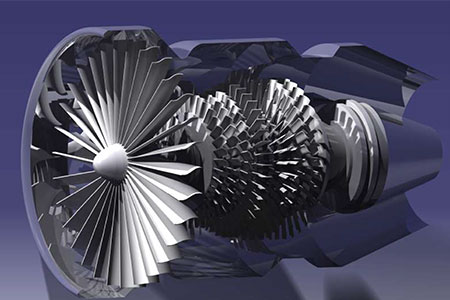

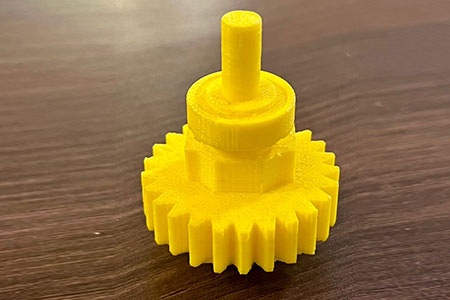

The course on parametric modeling trains you in the CATIA/SOLIDWORKS software and imparts knowledge about designing objects or systems that model component attributes with real-world behavior. The topics covered under this course are:

Body in white or BIW is basically the body shell design of different automotive products like cars and other commercial vehicles. It is one of the stages in automobile manufacturing in which Car’s body parts are assembled using one or different techniques. This course equips you with the knowledge of advanced 3D design provides insight on Sheet Metal Forming process, BIW assembly procedures, surface modeling, and GD&T. The topics covered under this course are:

The reverse engineering course in Automobile designing equips you with the knowledge of converting the physical data into digital data through the use of laser scanners or computed tomography (CT). With this course you learn to use CATIA- DSE, QSR software, and acquaints you with the following topics:

CFD is used to analyze the fluid flow in automobiles using numeric analysis. By taking the CFD course students learn about the application of ANSYS FLUENT software for different automotive design processes, such as liquid and gas flow with heat transfer, external and internal fluid flows, and much more. The topics covered under this course are:

Intensely focused on job readiness, the program devotes 70% of the training for projects and activities, adhering to standards and guidelines governing product designs, such as:

Training is offered at CADD Centre’s smart, hybrid learning centre in Chennai, completely equipped for online and in-person classes. With access to mentors and experts throughout the training period, students carry out projects at this custom-built training environment.

The course includes traditional hand processes and emerging technologies. You’ll participate in automotive sketching, clay modelling and handwork and have access to 3D printing at the design studio.

| Expert Mentoring to evaluate existing skills, aptitude, and thus identifying skill and will gaps required for the career |

| Projects The prime objective of this program is to equip learners with industry-ready skills through project-based and hands-on learning. |

| Industry Visits As the course progresses, industry visits for students to interact with professionals and experience a real-world design, engineering, and production environment |

| Portfolio Real world projects under each module including design and BIW to help students build a rich project portfolio demonstrating their unique talents |

| Workshops and Seminars by experts from the industry on specific skills, competencies, and emerging technologies |

| Placements Streamlined processes in organising interviews for students for internships and suitable jobs at chosen companies and regions |